- UK +44 1530510113 Germany +49 151 56363917 USA +1 (631) 387-4443

- About

- Case Studies

- News

How do you prototype?

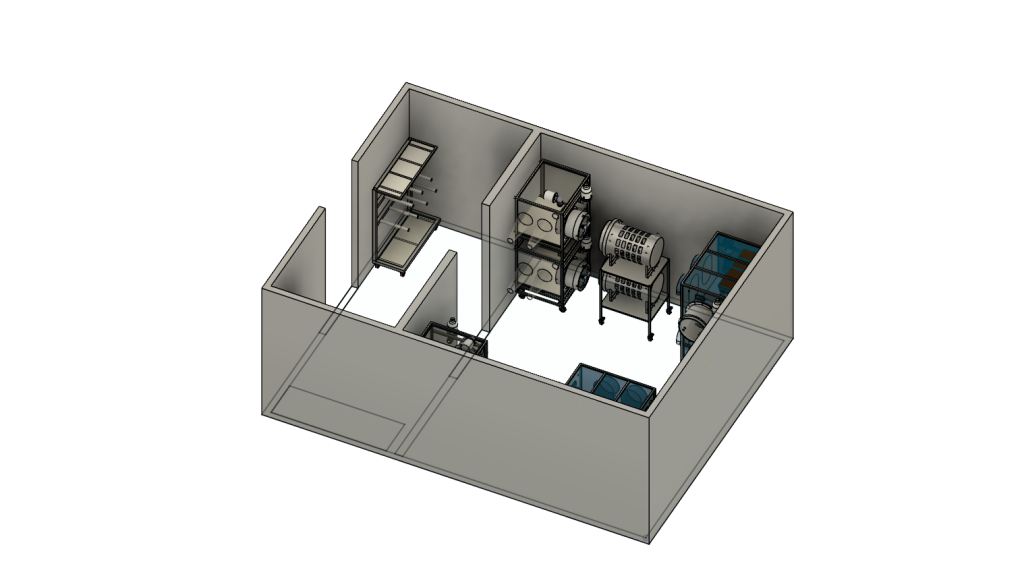

For us, prototyping isn’t just part of the process, it’s how we turn unique challenges into custom solutions.

Every project we take on is different, which means every prototype is too. Behind every finished NKP-Isotec product lies months of design work, revisions, and refinement. Ideas are tested, reshaped, and improved until the right solution emerges.

Prototyping is where creativity meets precision. It’s where an initial concept becomes something tangible, a piece of equipment built not just to function, but to fit seamlessly into the way our clients work.

We work closely with our clients throughout development, exploring the details that make their process unique. Each prototype is a conversation, between engineers, designers, and users, to ensure that the final design truly serves its purpose.

That collaboration allows us to deliver equipment that’s tailored, reliable, and ready for real-world use. Because when every lab operates differently, custom products make all the difference.

In a world that values speed and standardisation, taking the time to prototype properly sets NKP-Isotec apart. It’s a commitment to craftsmanship, ensuring that every piece of equipment reflects both the needs of the user and the expertise of the maker.

For us, prototyping is more than a phase. It’s the foundation of innovation, precision, and partnership.